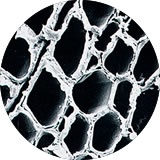

Mineralised fir wood wool bound with Portland cement.

CELENIT is a natural and sustainable insulating material, made only with natural materials: wood, Portland cement, marble dust and water. In fact, it uses fir wood from sustainably managed forests (PEFC™ or FSC® certificate). CELENIT products are not harmful for human health and the environment and the low energy production process creates limited emissions into the atmosphere (ANAB-ICEA and nature plus certificate). It uses recycled materials such as calcium carbonate, which is the residual dust of marble processing (ICEA certificate). Finally, the raw materials are close to the production establishment (regional material). For all these reasons, CELENIT panels can be used in projects that require building sustainability certificates such as Leed, SBtool, SB100, and Breeam.

CELENIT boards are made up of wood wool and mineral binders, mainly Portland cement and marble dust.

Fibres are mineralised, a treatment that, while retaining the mechanical properties of wood, blocks the process of biological deterioration, making the fibres perfectly inert and increasing the level of fire resistance. Fibres are then coated with Portland cement and bound together under pressure to form a stable, resistant, compact and durable structure.

The cellular structure of the wood gives the insulating panel lightness and elasticity; the irregular texture and the gaps between fibers ensure sound absorption and an excellent grip to all types of mortars. The wood wool and Portland cement mix, joined under pressure, determine compactness and strength, two qualities that are always appreciated in the construction industry; the presence of Portland cement ensures high resistance to water and frost, superior mechanical properties such as bending and compressive strength.

The cellular structure of the wood gives the insulating panel lightness and elasticity.

The irregular texture and the gaps between fibers ensure sound absorption and an excellent grip to all types of mortars.

The wood wool and Portland cement mix, joined under pressure, determine compactness and strength, two qualities that are always appreciated in the construction industry.

The presence of Portland cement ensures high resistance to water and frost, superior mechanical properties such as bending and compressive strength